Surprising fact: many Australian homes fitted in the first wave of double glazing are now near the 20‑ to 50‑year mark, so owners face real choices about performance and value.

This guide answers the key question homeowners ask about durability, service life and value. You’ll get clear timelines, warning signs and simple maintenance steps that help protect comfort and energy bills.

Longevity varies with build quality, installation standards, climate exposure and care. Coastal salt spray, strong UV and bushfire‑adjacent heat all affect glazing and seals.

Beyond warmth, benefits include quieter rooms and better energy efficiency. Typical failures start with gas loss in IGUs and degraded perimeter seals, which show up as misting or draughts.

We explain warranties, retrofit options for existing frames, full replacement triggers and new tech like vacuum insulated glazing. For tailored advice or a fast quote, call 0440 138 658.

Key Takeaways

- Average quoted lifespan is ~20 years; well‑built systems can reach 50 years.

- Performance depends on build, installation, local climate and maintenance.

- Misting and draughts usually signal IGU seal or gas loss issues.

- Warranties are often 5–10 years; treat them as a minimum benchmark.

- Options include maintenance, IGU retrofit, or full replacement with newer tech.

- Check windows before peak heating or cooling seasons to avoid bill shock.

Quick answer: average lifespan and what affects it over time

Headline figure: most Australian homes see strong performance for about 15–20 years, while top-tier systems in mild exposures can continue working effectively for up to 50 years.

Typical ranges

The common service life sits between 15 and 20 years. Premium specification, careful installation and sheltered orientation push that toward several decades.

Why guarantees are shorter

Manufacturers typically offer 5–10 year guarantees on gas-filled units. These warranties cover defects, not total expected life. Gas depletion often reduces insulation in the 10–15 year period, but performance falls gradually rather than overnight.

- Key factors: build quality, glass and spacer choice, installation craft, orientation and exposure to sun, salt or storms.

- Individual panes in one home can age at different rates depending on direction and use.

- Basic maintenance — clearing drainage and checking seals — delays decline and protects comfort and energy bills.

If you want a quick assessment of your current setup, contact an experienced installer on 0440 138 658 for an on-site benchmark and sensible next steps.

How long do double glazed windows last in Australia?

Exposure to intense sun, salt air and storms shapes service life across states and suburbs. Australia’s broad climate zones mean units in coastal, tropical, inland and alpine areas age differently.

High UV and heat accelerate seal ageing and gas diffusion. Storms and salt‑laden air attack frames, drainage and external seals, increasing risk of corrosion and other damage.

Orientation matters. Sun‑facing elevations in hotter regions face wider temperature swings and earlier fatigue. Dark frames or low shading raise surface temperatures and put extra stress on the insulating unit.

Market context and practical checks

- Many Australian homes from the industry’s first wave are now mid‑life, so more units need inspections or replacement within a few years.

- Prioritise inspections on the most exposed elevations first; they usually show symptoms sooner than shaded aspects.

- Coastal homeowners should specify corrosion‑resistant hardware and maintain rigorous cleaning and drainage checks to reduce saline impact.

- Specifying wider cavities or advanced spacers in harsh exposures can slow performance decline and reduce noise and thermal losses.

What actually fails in double glazing: IGUs, gas loss and seals

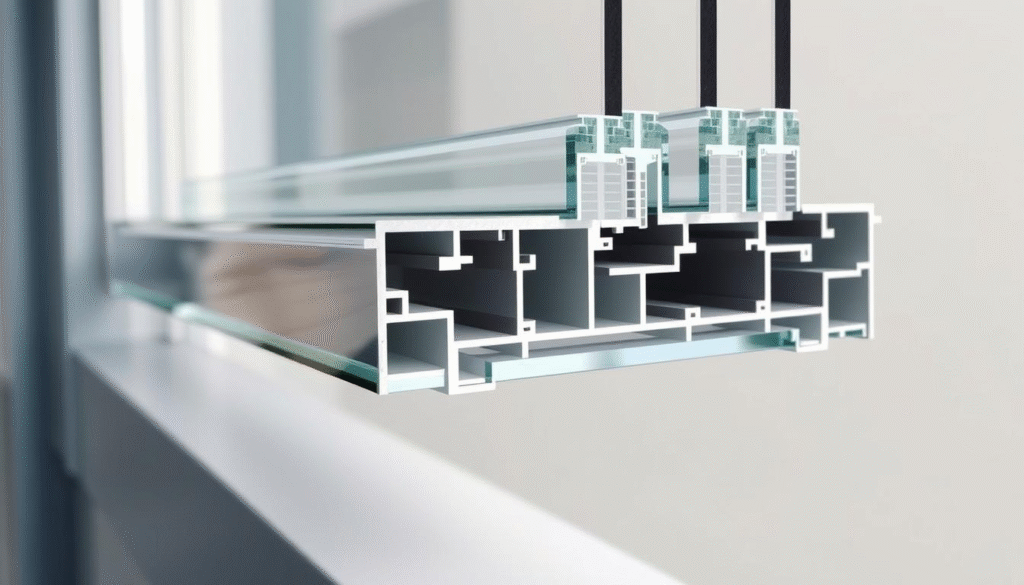

A sealed insulating unit is a system of parts, not a single pane. An IGU normally has two panes separated by a spacer with an inert gas in the space between them. This design cuts conductive and convective heat transfer and improves comfort.

Insulating glass unit basics: panes, spacer and gas-filled space

Definition: the glass unit is two glass panes, a spacer and a sealed cavity filled with argon or another inert gas to boost insulation.

Gas depletion timeline and efficiency effects

Gas slowly diffuses over years. When roughly a quarter escapes, U-values fall and heating or cooling costs rise noticeably.

“A partially depleted unit looks fine but performs worse — energy bills often show the change before owners do.”

Perimeter seal degradation: tiny breaches, big losses

Micro-gaps allow warm air and moisture vapour to enter the cavity. That leads to condensation or lasting misting that cannot be wiped away.

- Even tiny leaks reduce insulation and can start corrosion at metal spacers.

- Thermal cycling stresses adhesives and hastens seal failure on sun‑exposed elevations.

- Good drainage and wider cavities with warm‑edge spacers improve durability in harsh climates.

Inspect from different angles and times of day to spot early haze. Once an IGU is blown, replacing the glass unit is usually the practical fix to restore efficiency and prevent secondary damage.

Clear signs your double glazed windows are past their best

A few clear symptoms indicate an insulating unit or frame is no longer performing as intended. Spotting these signs early helps protect comfort and avoids bigger damage.

Condensation or misting between panes

Between‑the‑panes haze is the hallmark of a blown unit. This condensation cannot be wiped away and often worsens after temperature swings.

Feeling draughts and cold air

Run your hand around seals on windy days. Cold air entering at the perimeter is a simple sign of seal failure or frame gaps.

Rising energy bills and longer run times

If heating or cooling runs more often, energy bills give an early financial clue that insulation is failing.

Chips, cracks, leaks and mould risk

Visible chips or cracks let in water during severe weather. Persistent damp leads to mould and secondary damage to timber or drywall.

Stiff operation and hardware wear

Hard‑to‑open sashes, worn hinges and faulty latches point to frame movement or ageing components that affect weatherproofing.

- Compare different elevations: exposed aspects usually show issues first.

- Photograph problems with dates to track progression and support claims.

- Leaving a blown unit in place may cause staining and frame swelling over time.

- Prioritise repairs in bedrooms and living areas where comfort matters most.

| Sign | Likely cause | Suggested action |

| Between‑pane condensation | Failed seal, gas loss | Replace IGU or retrofit unit |

| Perimeter draughts | Worn sealant or frame gap | Re‑seal or adjust frame hardware |

| Water stains after storms | Weather seal failure, leaks | Repair flashing, treat mould, consider replacement |

Factors that shorten or extend lifespan

Several construction and material choices set the pace at which a unit ages.

Robust specification and tidy installation extend service life and keep efficiency high.

Build and spacer technology

Manufacturing quality matters: consistent seals, durable spacers and correct gas fill keep assemblies tight.

Choosing better glass coatings and a wider cavity can slow thermal stress and help the glazing last longer.

Installation and frame choice

Good installation prevents racking and protects seals from strain.

Frames differ: uPVC needs little maintenance, thermally broken aluminium controls heat flow, and timber must be maintained to avoid movement.

Exposure and maintenance

Unshaded or coastal faces see harsher weather and age faster. Design clear drainage paths and use flexible sealants to allow thermal movement.

Regular cleaning, drainage checks and hardware alignment reduce seal failure and keep units performing for years.

| Factor | Impact | Practical step |

| Manufacturing quality | Higher durability, fewer failures | Specify consistent seals, warm-edge spacer |

| Installation fit | Less frame stress and leaks | Use skilled fitter, ensure square seating |

| Exposure | Faster ageing in sun/salt | Prioritise corrosion-resistant hardware |

| Maintenance | Delays seal failure | Regular drains, gaskets and cleaning |

Takeaway: a holistic approach — good product, careful installation and simple upkeep — gives the best chance of decades of reliable performance from long double glazing.

Making windows last longer: practical maintenance and upgrade tips

A few targeted maintenance tasks each year can protect seals and retain insulation performance. Small checks and timely fixes reduce moisture risk and keep energy bills in check.

Seal care, drainage checks and cleaning that protect the IGU

Seasonal cleaning of frames and glass prevents grit buildup near seals. Clear weep holes and drainage channels to avoid standing water that invites seal failure.

Use mild detergents and soft tools to preserve gaskets, sealants and coatings. Inspect perimeters for hardening or shrinkage and address gaps early.

When a larger cavity or different spacer makes sense in harsh climates

In hot, high‑UV or alpine areas, a wider internal gap and warm‑edge spacers reduce thermal stress and slow degradation. These choices help the unit cope with big temperature swings and lower ongoing energy use.

Retrofit options: replacing the glass unit vs full frame replacement

Replacing only the failed glass unit is often the least disruptive route when frames remain sound. This restores insulation and can include higher‑spec coatings and improved spacers to lift performance.

Choose full frame replacement if frames are warped, corroded or thermally inefficient. Correct installation with square seating and proper packers prevents point loads and early seal stress.

- Lubricate hardware and check gaskets to keep operation smooth.

- Document repairs and dates for future assessments and warranty claims.

- Consider upgraded coatings and spacers during IGU replacement to boost thermal performance without altering appearance.

“Regular checks and timely small repairs often save the cost and hassle of a full replacement.”

Need maintenance advice or a retrofit quote? Call 0440 138 658 for an on‑site assessment and practical options tailored to your home.

When to replace double glazing and emerging alternatives

Replacement becomes sensible when recurring faults outstrip the cost and benefit of repairs. Consider age, measured performance and the likelihood of the same problem appearing on other elevations.

Decision cues: multiple clear signs — persistent misting, draughts at the perimeter, recurring water leaks or rising heating use — usually justify replacement rather than repeated patch repairs.

Decision cues: performance drop vs age vs repair costs

Weigh an individual quote for a glass unit repair against the probability of another unit failing within a few years. Replacing several failing units at once often reduces labour costs and restores consistent appearance and performance.

Vacuum insulated glazing (VIG): thinner units, higher insulation, 15-year guarantees

VIG uses a vacuum cavity instead of gas to deliver low U-values in a slimmer profile. It suits space- or weight‑constrained openings and commonly carries around a 15 years guarantee, while many gas-filled IGUs offer 5–10 years.

Balancing efficiency gains with energy bills and comfort

Compare whole‑of‑home comfort and projected savings in energy bills against the upfront cost. Ask installers for U-value and SHGC targets tailored to façade orientation and local climate.

- Prioritise acoustic and safety glazing needs, and check bushfire zoning rules.

- Schedule upgrades ahead of peak heating or cooling seasons to avoid bill spikes.

- Shortlist local installers with strong references and clear, itemised quotes.

| Trigger | Typical action | Benefit |

| Misting and moisture inside unit | Replace IGU or consider VIG | Restores insulation and prevents frame damage |

| Recurring water leaks or seal damage | Repair flashing; replace multiple units if recurrent | Reduces repeated costs and fixes secondary damage |

| Low efficiency and rising bills | Compare retrofit with full replacement using U‑values | Optimises comfort and lifetime savings |

“Replacing several units at once can deliver better value and a uniform finish.”

Your next steps: assess, compare and get expert help today

Record visible defects and room comfort issues to build a sensible upgrade plan.

Start with a simple audit: list rooms with poor comfort, photograph misting, cracks, water marks and stiff panes. Gather purchase records to confirm age, specs and remaining warranty.

Decide whether to target the worst-performing glazed windows first or stage works by elevation for budget control. Request quotes that compare replacing the glass unit against full frame replacement with clear U-values and warranties.

Ask companies to name spacer type, cavity size, coatings and expected service life. Keep a maintenance checklist for drains, seals and operation, and schedule work before peak heating season.

For a tailored inspection and clear options, call 0440 138 658.

FAQ

What is the typical lifespan of modern insulated glass units in Australian homes?

Most insulated glass units perform well for around 15–20 years. In ideal conditions — quality materials, skilled installation and low exposure to harsh weather — some units can continue to work effectively for up to 40–50 years. Manufacturer guarantees are usually shorter than real-world life because warranties cover specific failures, such as gas loss or seal failure, rather than gradual degradation.

How do Australian climates affect window performance over time?

Exposure to intense sun, high UV levels, coastal salt spray and frequent storms accelerates seal wear and frame corrosion. Northern and western aspects that face strong afternoon sun place extra thermal stress on glass and spacers. Coastal homes often need corrosion-resistant hardware and higher-spec seals to maintain performance.

Which components tend to fail first in an insulated unit?

Perimeter seals and spacer systems typically fail before the glass itself. Small breaches in the seal allow moisture and air into the cavity, causing misting between panes and gradual loss of inert gas. Once gas pressure and composition change, thermal efficiency and U-values drop noticeably.

What are the clear signs an insulated unit needs replacing?

Visible condensation or misting between panes, cold or draughts at the frame, rising heating bills, visible cracks or chips in the glass, difficulty operating the window and mould around seals are all strong indicators the unit is past its best and should be assessed.

Can poor installation shorten the life of my glazing?

Yes. Incorrect fitting, inadequate drainage, damaged frames or poorly sealed joins increase stress on the unit and let moisture in. Professional installation that follows manufacturer guidelines and uses appropriate flashings and sealants helps extend service life significantly.

How fast does gas depletion affect energy efficiency?

Inert gas such as argon can leak slowly over several years. As gas concentration falls, thermal resistance reduces and U-values worsen. Homeowners may notice higher energy use and less comfortable rooms before any visible misting appears.

What maintenance prevents early seal failure?

Regular cleaning of frame channels, ensuring drainage holes remain clear, lubricating hardware and inspecting seals for cracks or gaps all help. Avoid high-pressure cleaning directed at seal lines and replace damaged sealant promptly to prevent moisture ingress.

Should I replace just the glass unit or the whole frame?

If frames remain square, undamaged and thermally sound, replacing only the insulating glass unit is often cost-effective. If frames show rot, corrosion, warping or modern performance upgrades are desired (better thermal breaks, improved weatherproofing), full frame replacement may be the better long-term investment.

What upgrade options improve insulation beyond standard units?

Higher-performance options include larger cavity widths, warm-edge spacers, low-emissivity coatings and vacuum insulated glazing (VIG). VIGs give excellent thermal performance in a much thinner unit, though availability and upfront cost vary. Choose upgrades that match your climate and budget for the best results.

When does it make sense to replace units rather than repair them?

Replace when misting is widespread, energy costs rise noticeably, operation becomes difficult, or repair costs approach replacement price. Also consider replacement when long-term efficiency benefits (lower bills, improved comfort) justify the investment.

How do I choose a reputable installer or company in Australia?

Seek installers with proven experience in local climates, positive customer reviews, clear guarantees and accreditation from recognised industry bodies such as the Australian Glass and Glazing Association. Ask for written warranties on both product and installation and request references from recent projects.

Can small chips or cracks be repaired without replacing the unit?

Surface chips in the outer pane sometimes can be repaired, but cracks that penetrate or affect sealing usually require unit replacement. Even small breaches can lead to seal failure and moisture ingress over time, so inspect and address damage promptly.

How often should I inspect window seals and hardware?

Do a visual inspection and basic operation check at least once a year. After severe storms or high winds, recheck drainage, seals and locking hardware. Early detection of minor issues prevents costly failures later.

What impact do failing units have on energy bills and comfort?

Lost gas and degraded seals reduce thermal resistance, so heating and cooling systems run longer to maintain comfort. Homeowners often notice chillier rooms, colder surfaces and higher energy use before visible signs like misting appear.

Are warranties reliable indicators of expected life?

Warranties show manufacturer confidence for specific failure types and periods. They don’t guarantee the full working life of a unit because external factors such as installation quality, exposure and maintenance also determine longevity. Use warranties alongside product reputation and installer credentials when choosing upgrades.